- UpperEdge

- Reading Time: 5 minutes

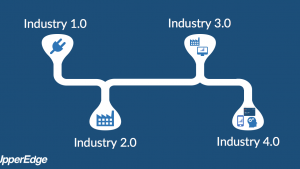

Today’s disruption of manufacturing is often described as Industry 4.0. Many see the term and ask, “But what was 1.0, 2.0 & 3.0?”

Simply stated, Industry 1.0 was when electricity was added to the manufacturing process to create machines to replace human labor (thanks Thomas Edison). Industry 2.0 was when these machines were integrated into a process to create factories (thanks Henry Ford). Industry 3.0 was when we added computers and spreadsheets to the manufacturing process (thanks Bill Gates). And with present day 4.0 we have advanced and integrated technologies to further automate, with capabilities such as machine learning, artificial intelligence, data analytics and mobility (thanks Steve Jobs).

Each X.0 revolutionized the way we manufacture products and replace/exceed human capabilities to new scales and efficiencies.

Case Study: Consumer Products

A consumer products company was seeking to meet proposed industry regulatory requirements combined with improved productivity, product quality, safety, customer fulfillment and other key measures. They took a technology-driven approach due to concerns with the abilities and capacity of their existing workforce to learn and execute the disciplines required to meet their objectives. They also needed to replace their aging technology infrastructure.

The functional scope of the program was enterprise-wide and included Finance, Supply Chain, Warehouse Management, and Sales through to Manufacturing and Operations. Technologies and capabilities they leveraged included ERP, MES, EAI, MDM, Analytics, Wireless, RFID and PLC’s. The program was greenfield as legacy integrations were minimized, but the overall complexity based on breadth of scope, newness of technology and change management made the program very complex. The lessons learned spanned from strategy, to process and methods, to people and technology.

Lesson 1 – IT and Engineering Collaboration

In many respects IT and engineering organizations are like oil and water that do not easily mix. One group is disciplined with their methodology while the other is agile; one inclusive & consensus-driven and the other independent. If mismanaged, scope is missed, integrations fail, timelines slip and ultimately budgets and solutions are broken. Alignment requires several tactics focused on allying methodologies, approach, people, integrations, and solution. Such tactics include co-location of teams, aligning program phases and deployments, the setting up of integration roles and strong single governance models.

Lesson 2 – Error and Exception Handling

When mixing technology with machinery and humans what can go wrong will go wrong. The solution needs to be able to identify errors, log exceptions and, when possible, automatically correct issues in a manner that does not impact the process. Designs not only need to define the “normal” process but identify failure points and how the systems would mitigate, resolve, or continue operating for acceptable periods of time while exceptions are handled. Physical barriers, technology failures, human error, and environmental situations need to be identified, prioritized, accounted for, and testing these scenarios in the physical location is necessary. Integration software requires robust capabilities to log and correct errors and retransmit messages, while each application needs to account for the exceptions with the ability to continue processing.

Lesson 3 – Integration, Integration and Integration

Complexity of integration comes from the volume of transactions, number of communication layers and communication points, process/data dependencies, timing and sequence dependencies. When a process or scenario requires data from a mobile device, machine PLC, and data from an RFID chip, the integrated design needs to anticipate out-of-sequence events, missing data and exceptions. Communication or data batching needs to consider lag times. Performance and integration testing needs to account for exceptions and the execution of end-to-end scenarios to prove out the design. Storing data within a device, setting up of delayed batch times, synchronizing clocks, and setting timestamps are some of the options that the design needs to consider when integrating real time processing across multiple platforms and devices.

Lesson 4 – Analytics Operating Model

Capturing significant data across an enterprise creates substantial opportunity to leverage the data to improve operations and company performance. To capture value from data, the solutions need to consider a top down and bottom-up approach. Analytical scenarios are identified within the design and built into the solution while the process is expanded to capture data for future scenarios and analysis. Testing the identified use cases will ensure value can be extracted. The business should align the operating model for each level and role in the organization to use the data and insights to more effectively execute the process. KPI and data reviews from line managers to shift supervisors, all the way to the C level, should be built into the new operating model.

Lesson 5 – Value

Capturing value from Industry 4.0 is critical to the success of the program. Many of the lessons learned are captured in our blog, “Capturing the Value of Business, Digital and Technology Transformations.” The critical value lesson related to Industry 4.0 is the understanding that Good + Good + Good <> Good. Therefore, in optimizing specific operational processes you need to consider the tradeoffs with the overall business strategy in order to achieve a greater good.

Lesson 6 – Crawl, Walk, Run

When combining tens of thousands of data points from RFID tags, PLC’s, and mobile devices to back end systems, there are going to be issues. To test every scenario would raise the costs of any program and may prevent it from ever beginning. There are also risks from users not trusting data, to customers not receiving the right product. Several items need to be mapped out, from process contingencies, to a capability release schedule, to expectation-setting through various testing approaches to achieve stability, trust within the system and to extract value.

New technology solutions and innovation continue to improve automation and insights into manufacturing operations that are spurring Industry 4.0, but there is still significant complexity in the integration of data and systems. Building a solution that accounts for human, technology and environmental errors, aligning your organization and operating model to leverage the data, and aligning the approach to build confidence in the solution all contribute to the successful outcome and ability to achieve value.

12 Questions to Ask Your Vendors on Your Industry 4.0 Transformation:

- How does your proposed methodology account for the culture and approach differences in methods between IT & Engineering?

- Describe the data flow across the various levels and/or platforms and the design considerations at each level to ensure business continuity and data accuracy.

- Define the types of exceptions and errors that would be expected by the proposed solution or scope. Describe how your methodology tests these types of exceptions and errors.

- Describe how your integration design addresses device, PLC or message failure and communication lags.

- Describe how your test approach identifies, prioritizes and tests various exceptions and errors.

- Describe how your testing approach tests physical and human interaction scenarios.

- Describe the factors considered to estimate exceptions and errors. For each factor, describe the units and how increases and decreases would be handled with a change order.

- Define leading analytics operating model(s) and how your approach would confirm and implement the appropriate model.

- Based on the company’s industry, provide sample KPI’s and measures for the proposed solution for each level of the operating model from CXX to Line Supervisor.

- Describe how your approach integrates the performance tradeoffs between process and function to align the solution to the business strategy.

- Describe the several types of deployments that may be considered for this program. Define what factors should be considered when choosing a deployment option and describe how your approach will determine or confirm the assumed approach.

- Describe how your proposed approach mitigates risk associated with data inconsistencies and anomalies typical with new system startups – including lack of historical data, missing data, startup errors, etc.

To learn more about how UpperEdge is helping clients with their Industry 4.0 transformation please contact us.