- John Belden

- Reading Time: 4 minutes

A Costly ERP Mishap Highlights the Risks of Poor Readiness and System Integration Challenges

What Happened with Mohawk Industries’ ERP Implementation?

In early 2025, Mohawk Industries, a global flooring manufacturer, faced significant operational disruptions following the rollout of a new order management system for its Flooring North America segment. The implementation was intended to streamline operations but instead resulted in widespread shipping and invoicing errors, ultimately affecting service levels and financial performance.

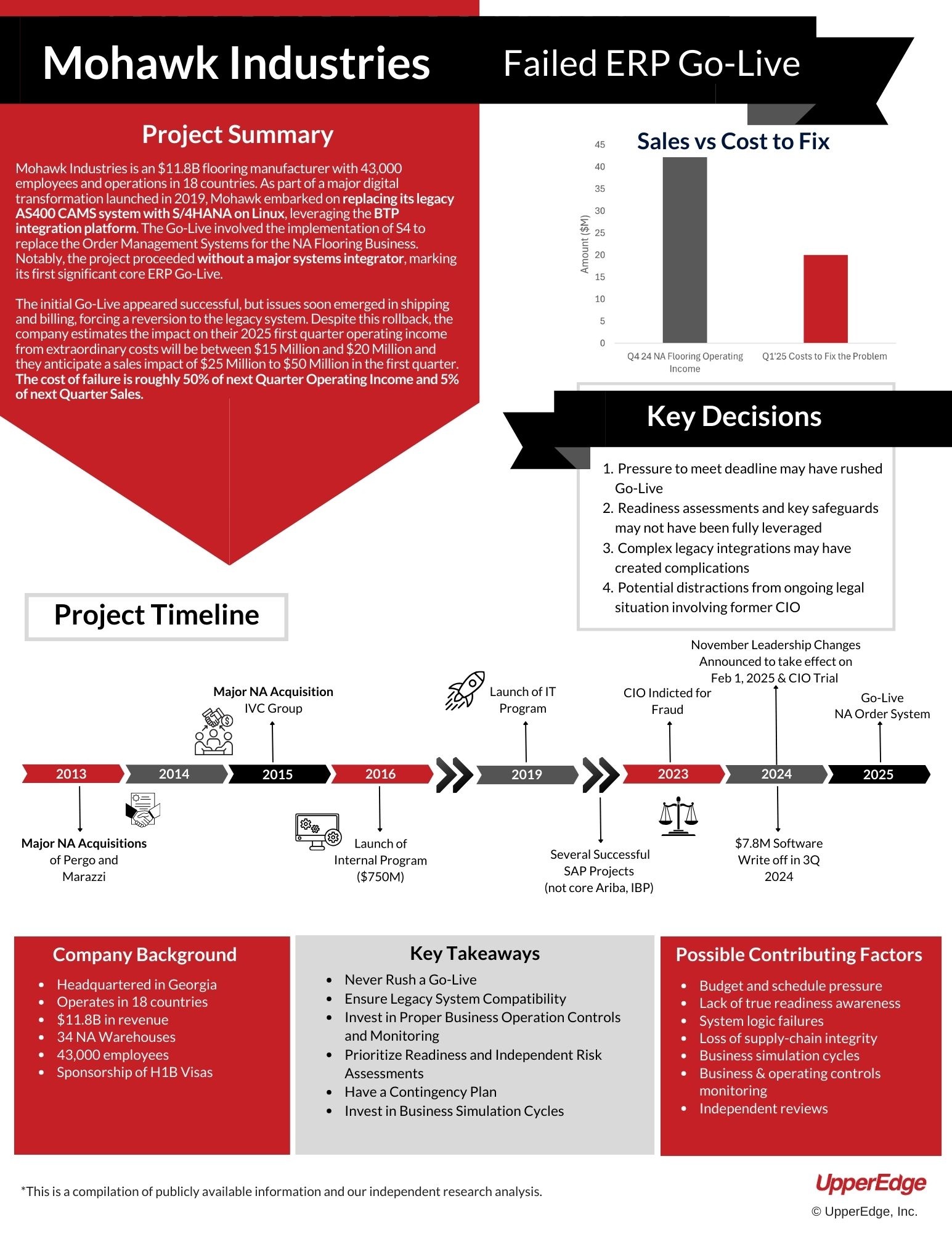

Despite being able to revert to the previous system, the company estimates the impact on their 2025 first quarter operating income from extraordinary costs will be between $15 million and $20 Million and they anticipate a sales impact of $25 Million to $50 Million in the first quarter. This would mean that ultimately, the cost of this failure is roughly 50% of next Quarter Operating Income and 5% of next Quarter Sales. Like so many other IT transformation disasters, this incident underscores the risks of ERP go-lives and the importance of a comprehensive readiness evaluation.

Why Did Mohawk’s ERP Implementation Fail?

The failure of Mohawk’s ERP system can likely be attributed to several factors:

- Budget and Schedule Pressure: Mohawk Industries’ project was up against a January 1 deadline, so it is possible that the decision to proceed with the ERP go-live was driven by meeting this deadline, which may have impacted the execution of critical risk-mitigation activities.

- Inadequate Readiness Assessments: Around the same time that the ERP was set to go-live, the company was facing an ongoing legal situation involving the former CIO which may have caused distractions among internal employees that could have impacted their ability to perform adequate readiness assessments.

- Legacy System Complexity: Many organizations face complexities in integrating legacy supply chain systems, particularly AS400 CAMS, that may have created complications between the SAP order system and WMS in Mohawk’s case.

- Potential Gaps in Risk Management: Given the urgency to meet the January 1 deadline, combined with the legal and operational challenges Mohawk was facing at the time, it is reasonable to speculate that key safeguards—such as business simulation cycles and independent validation—may not have been fully leveraged before the go-live date.

Despite these challenges, Mohawk’s ability to revert to its previous system suggests a degree of foresight in contingency planning. However, persistent issues in inventory accuracy, billing, and financial controls could indicate that deeper integration and validation efforts were needed before full deployment. Moving forward, supply chain integrity testing, comprehensive business simulations, and independent risk assessments should be prioritized to enhance stability and ensure long-term success.

What Has Mohawk Done to Fix the Problem?

Mohawk Industries has taken corrective actions to stabilize operations. The company reverted to the previous system and has addressed major system errors, bringing shipping rates and backlog levels back to normal. Mohawk is actively working with customers to resolve order and invoicing discrepancies. Leadership is also implementing cost-cutting and restructuring initiatives to offset losses. However, despite these efforts, the long-term impact on customer trust and operational efficiency remains uncertain.

How Much Did the ERP Failure Cost Mohawk?

The financial impact of the system failure was severe:

- $25 Million – $30 Million in Estimated Q1 Losses: Mohawk estimated the impact on their first quarter operating income from missed sales and extraordinary costs will be between $25 million and $30 million. $15 million to $20 million of that will go towards the additional hours and processes needed to correct the system. The sales impact is anticipated at $25 million to $50 million in losses in the first quarter.

- Stock Performance and Earnings Impact: While Mohawk reported net earnings of $93 million for Q4 2024, its earnings per share (EPS) of $1.48 fell short of Wall Street expectations. These results may indicate additional project costs required leading up to the go-live.

- Ongoing Remediation Costs: The company continues to invest in fixing system integration and billing issues, adding further strain to financial performance.

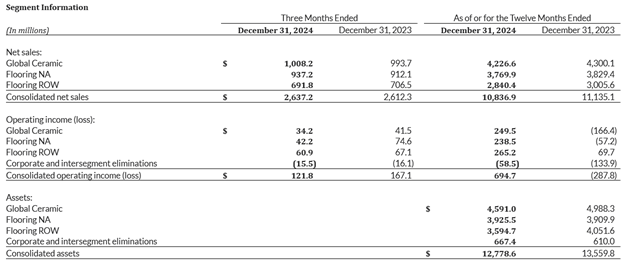

To add context to the financial impacts of this system failure, it is important to note that Flooring North America’s FY2024 sales were $3.8 billion, with FY2024 Q4 bringing in $937 million of that total. Their operating income for Q4 came in at $42.2 million. This means if we use Q4 results as a guide, the cost of this failure is roughly 50% of Mohawk’s next quarter operating income and 5% of next quarter’s sales.

Source: Mohawk Industries FY2024 Earnings Call

What Can IT Leaders Learn from Mohawk’s ERP Failure?

Mohawk’s experience offers key takeaways for organizations planning an ERP implementation:

- Never Rush a Go-Live: Tight deadlines without proper testing and validation can lead to costly failures.

- Ensure Legacy System Compatibility: Older systems must be carefully integrated or phased out to avoid unforeseen conflicts.

- Invest in Proper Business Operating Controls and Monitoring: Having a real time view of how the business processes are performing against a baseline can provide early warnings of potential problems as well as the lead time to fix them before they snowball.

- Prioritize Readiness and Risk Assessments: Leadership distractions and poor risk planning can derail even well-intentioned projects.

- Have a Contingency Plan: The ability to revert to legacy systems likely saved Mohawk from more significant losses, emphasizing the importance of backup strategies.

- Invest in Business Simulation Cycles: Rigorous pre-launch testing with real-world scenarios can expose issues before they become major disruptions.

Conclusion: A Cautionary Tale for Digital Transformation

Mohawk Industries’ ERP failure serves as a cautionary tale for IT leaders and enterprise decision-makers embarking on digital transformation initiatives. The company’s struggles with system integration, legacy integration, and go-live readiness highlight the importance of meticulous planning, proactive risk management, and thorough testing. Organizations looking to avoid similar pitfalls should take a structured approach to ERP rollouts, ensuring alignment between technology, business processes, and leadership priorities.

To ensure your ERP implementation programs stay the course with proper readiness assessments and risk management processes, contact UpperEdge to learn how we can help.

Related Blogs

Why 2026 Will Be a Defining Year for Enterprise SAP Negotiations

SAP Q4 FY2025 Earnings: Five Key Takeaways Heading Into 2026

Program Drift: The Hidden Threat to Your ERP Investment

About the Author